Because it Works!

The Best Material at Resisting Corrosion

— no coating failures

Because it is Cost Effective!

Operating Cost Savings makes it the

LOWEST Cost Option

Why use it? The simple answer:

It is proven to provide superior corrosion resistance ensuring long-term durability thus eliminating major repairs and extending the service life.

Keep the roads open and lower life cycle costs relative to other options.

That’s it!

Why use it? Decades of corrosion resistance field evidence matters.

85 years of Proven Service Life in Salt Water

Progresso Pier

Built in 1941 — Still in Operation.

TOP 10 REASONS TO USE STAINLESS STEEL REBAR

Superior Corrosion Resistance – Independent Science

Long Term Durability – Extended Service Life

Open Roads – Macro-Economic Benefits

Initial Cost Material Savings – Concrete Cover/Mix, Grade 80 Steel, Deck Protection, Bond and Development Length

Applications in Conventional, Special and Extreme Conditions

Availability – Rebar Supply and Accessories

1. Superior Corrosion Resistance

Owners want their structures to perform better over longer periods of time in environmental conditions which are excessively harsh. Stainless steel is the key.

Stainless steel is recognized as the best practical and widely available corrosion-resistant metal for chloride and other chemical environments.

A pier in the salt water of the Gulf of Mexico located near Progreso, Mexico was built with stainless steel in 1941 and is still in service today. This actual field record of success is proof of the performance of stainless steel.

Chemistry does matter. As does independent, unbiased corrosion resistance research (not predetermined results) which ranks this material well beyond as the top performer.

Information available upon request. Contact Us.

2. Long Term Durability and Extended Service Life

A shipping pier located near Progreso, Mexico exposed to the salt water of the Gulf of Mexico was built with stainless steel in 1941 and is still in service today. This actual field record of on-going use is testament to the durability stainless steel provides to structures.

The Illinois DOT conducted a study of building structures with a 100-year life span with different types of rebar. The option with stainless steel was projected not to require major repairs over the life span. All other options constructed with non-stainless steel rebar required numerous major repairs.

The vast evidence of corrosion resistance studies indicate that stainless steel is a vastly superior performer which results in superior long term durability.

Information available upon request. Contact Us.

3. Major Repair / Maintenance Cost Savings

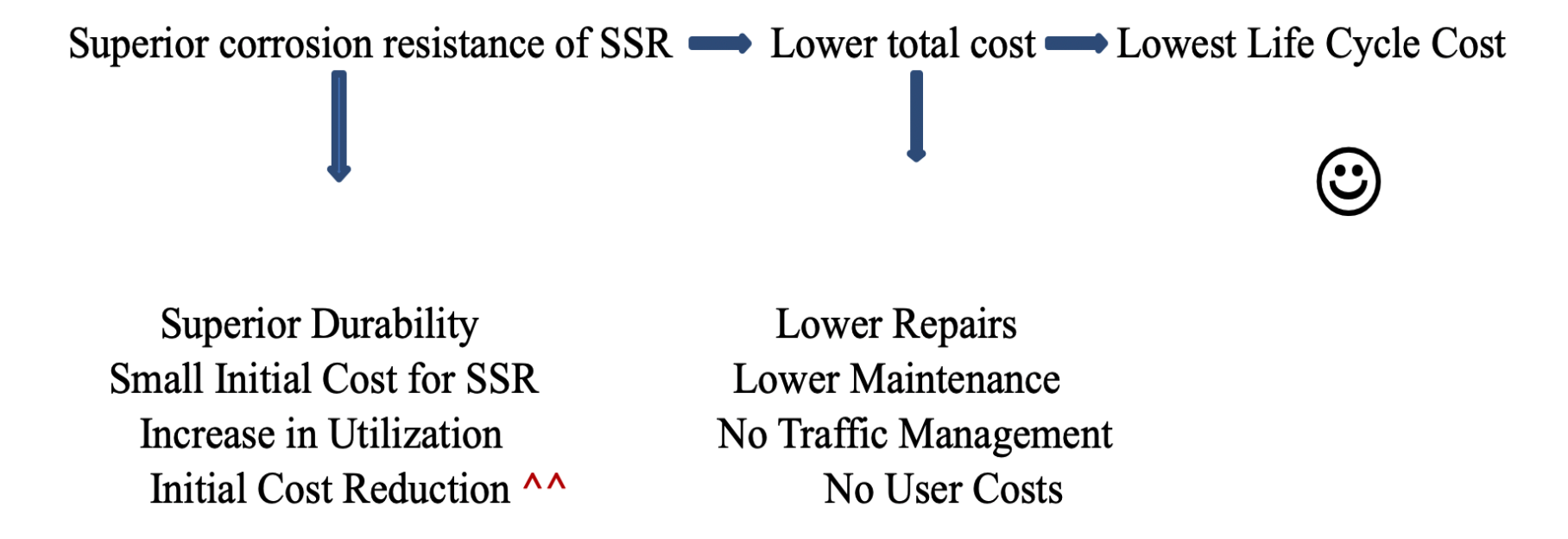

Avoidance of major repairs is the logical result of the superior corrosion resistance and extended long term durability of structures built with stainless steel rebar.

There are numerous studies such as those from the Illinois DOT and Indiana DOT which point to the long term durability and consequently the reduction in repairs associated with stainless steel.

Information available upon request. Contact Us.

4. Open Roads – Macro-Economic Benefits

Avoidance of major repairs is an outcome of the use of stainless steel rebar and its proven record of significantly increasing the long term durability of structures.

The uptime, or the utilization rate, and therefore the throughput of commerce and non-commercial highway traffic increases. User cost decline dramatically.

Information available upon request. Contact Us.

5. Lowest Life Cycle Cost

It is not rationale to expect that initial spending on low cost, inadequate materials will somehow result in long term durability, avoidance of major repairs and provide the lowest Life Cycle Cost.

Any actual rebar delivered initial cost impacts can be offset by cost reduction factors (less cover, etc.). The durability benefits of repair and maintenance savings, longer service life and increased highway throughput leads to LOWER LIFE CYCLE COST.

A recent study substantiates this claim.

The initial cost impacts of stainless steel are likely misrepresented.

Information available upon request. Contact Us.

6. Initial Cost Material Savings

There are several potential initial construction cost savings opportunities attributable singularly to the use of stainless steel rebar.

Material savings encompass reduction in concrete, changes in concrete mix design, leveraging high strength steel and elimination of deck protection systems.

Other savings relate to avoidance of field labor related to coatings repairs.

The bond strength and development length is the same as black bar.

Information available upon request. Contact Us.

7. Conventional Designs and Bar Sizes

Given that stainless steel has virtually the same Young’s Modulus as black bar, the design practices and procedures follow the same AASHTO and ACI conventions. See the page “Properties of Stainless Steel Rebar”.

The bar sizes and bend diameters are the same as black bar. See the page “A955 Bar Sizes.”

Information available upon request. Contact Us.

8. Applications in Conventional, Special or Extreme Conditions

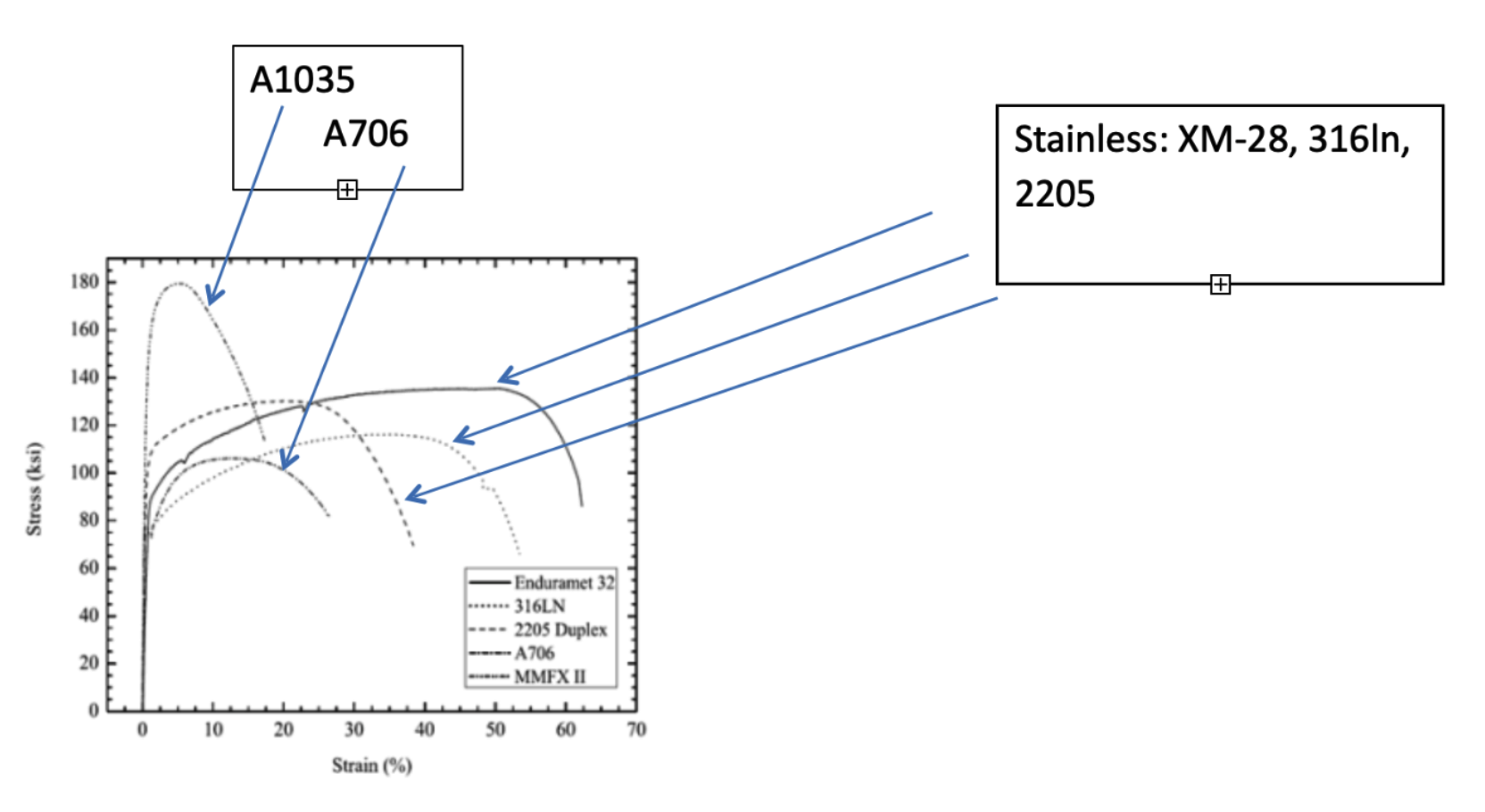

The following material properties are good reasons for using stainless steel.

Superior corrosion resistance is the product of choice for long term service life in a range of infrastructure and conventional structures exposed to corrosive elements.

For special applications such as seismic design, the austenitic alloy XM-28 in ASTM A955 display exceptional uniform elongation, well beyond any black bar.

Also, fatigue resilience is an important material property in special cyclical systems. Stainless steel is a superior performer.

In extreme conditions such as low and high temperatures, stainless steel maintains a high degree of its normal temperature yield strength capacity. Again, here it outperforms.

Likewise, its material toughness (Charpy values) at low temperatures is unmatched.

| Material Property | Application |

|---|---|

| Corrosion Resistance | Infrastructure and conventional structures exposed to corrosion. |

| Superior uniform elongation, ductility (request stress strain curves) | Seismic design |

| Extensive fatigue resistance | Seismic and other cyclic loading conditions |

| Low temperature toughness, maintaining yield strength (high Charpy values) | LNG, other cryogenic |

| High temperature, maintain yield strength | High temperature uses, fire rating |

| Low magnetic permeability | MRI’s, housing for sensitive electronics |

| Radiation tolerance | Nuclear |

| A955 Grade 80, high yield strength | Design economies |

Information available upon request. Contact Us.

9. Availability – Rebar Supply and Accessories

SSIG members have a well stocked inventory of all the common types and sizes of stainless steel reinforcing bar. Link to “ASTM A955 – Stainless Steel Standard” in “What is Stainless” and the “A955 Bar Sizes” file.

Stainless steel wire mesh and couplers are also stock items ready to be shipped.

Material can be shipped anywhere in the U.S.A. and in Canada.

Members can be contacted on the Contact Us page.

Information available upon request. Contact Us.

10. Fabrication Standard

Fabrication of stainless steel reinforcing bars is governed by the ANSI CRSI IPG4.1 document “Standard Practice for Stainless Steel Reinforcing Bar Fabrication Facilities”.

The fabrication processes, shipping and field handling procedures are the same as for uncoated carbon steel reinforcing bars with an emphasis on preventing contamination with black carbon.

Information available upon request. Contact Us.

75 yr. Positive Field Performance of Stainless Steel in Salt Water

The world’s longest pier (now 6 KM long) built in the Caribbean Sea in 1937-1941 still in use today.

The port city of Progreso, in the Mexican state of Yucatán, boasts of the longest pier in the world. The pier is also the first concrete structure in the world constructed between 1937 and 1941 with stainless steel reinforcement. Despite the relatively poor grade of concrete used, the pier has withstood the harsh marine environment and has been in continuous service for over 75 years without any major repair or routine maintenance activities.

The port city of Progreso, in the Mexican state of Yucatán, boasts of the longest pier in the world.

Aerial view of the 6km long Progreso Pier

Final Word: It May Cost more but it Works!

Structures built with stainless cost less

The benefits of using more durable materials results in lower cost infrastructure.

It’s Steel

Other non-steel bars made of composite materials are appearing on the market. These bars have different mechanical properties relative to steel notably that the allowable design strength is severely reduced due this material’s characteristic to lose strength over time, the strength in the transverse direction is very limited and the product is susceptible to degradation in humid conditions which calls into question the durability of this material.