ASTM A955/A955M Stainless Steel Standard

Standard Specification for Deformed and Plain Stainless-Steel Bars for Concrete Reinforcement

The ASTM A955/A955M standard specification is the accepted norm for the mill manufacture of stainless steel reinforcement. The standard has an international perspective though it is more prevalent in North America. A955 key points.

The main features of interest to stakeholders include :

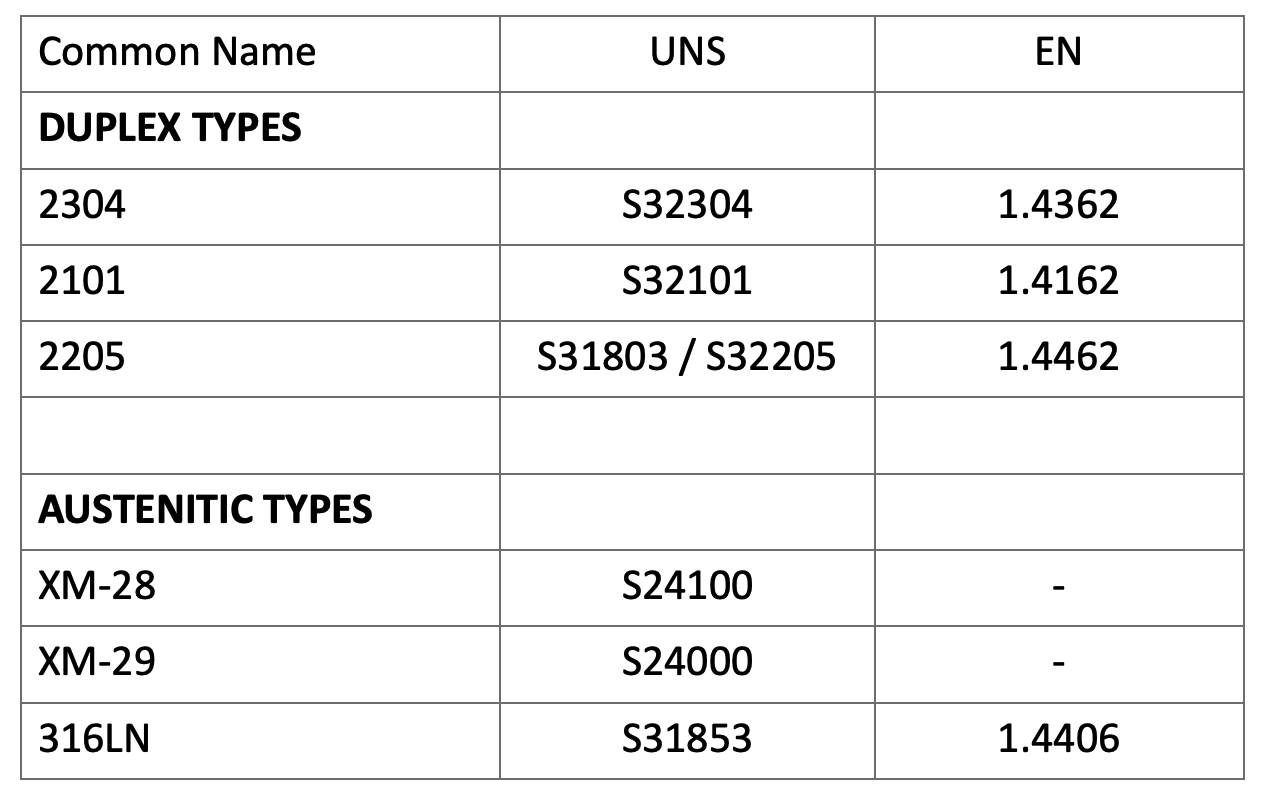

Inclusion of two stainless steel classifications – duplex and austenitic

A range of stainless steel chemical formulations

Mechanical and physical property requirements, and grade strengths available

Dimensional bar profiles, bar sizes, and bend diameters

Reference to surface quality and finish

A note that pickling is mandatory which improves the corrosion resistance

Grade structure (strengths) are equivalent to those of conventional black steel

Procedures for mandatory corrosion testing

A supplementary requirement pertaining to magnetic permeability

Requirements for adding new alloys

It is worth noting that A955 reflects the changing needs of users. As such the standard is frequently updated. A copy of the Standard can be obtained through ASTM.

AASHTO M 334M/M 334 Standard

Standard Specification for Uncoated, Corrosion-Resistant, Deformed and Plain Chromium Alloyed, Billet-Steel Bars for Concrete Reinforcement and Dowels

The AASHTO M 334 standard specification covers uncoated corrosion resistant steel reinforcement bars and dowels which includes stainless steel. Black carbon bar is not included. The content pertaining to stainless steel bars follows that of ASTM A955 though the group of alloys has not been adjusted to reflect A955. M 334M key points.

The main features of interest in this standard include :

It covers both A955 and A1035 (MMFX) material

The standard notes a possible limitation of coiled bar size based on equipment capacity

It provides guidance on the factors to be considered in specifying the degree of corrosion resistance

It includes three yield levels or grades which are similar to conventional black carbon steel

It lists the appropriate AWS welding code to be applied for the types of steel in the standard

The standard is in SI and inch-pound units; values are not necessarily equivalent

Of interest is the “Terminology” section which defines relevant terms such as corrosion-resistant, uncoated corrosion resistant reinforcement, deformed bar, etc.

M 334 includes the chemical composition for a range of types of stainless steel reinforcement, deformation and dimensional requirements for various bar sizes in SI and inch-pound units, strength properties, bending requirements, and surface finish requirements

It provides guidance on optional corrosion resistant test methods which can be used to evaluate the sensitivity of stainless steels to specific types of attack, and test methods to evaluate the comparative corrosion resistance of various steel bars.

A copy of the Standard can be obtained through AASHTO’s website.

AASHTO LFRD

Add contentBritish Standard BS 6744:2016

Stainless Steel Bars - Reinforcement of Concrete - Requirements and Test Methods

British Standard BS 6744 is more than a mill manufacturing standard. It also outlines a prescriptive-based guidance on the durability of reinforced concrete and a corrosion resistance test method. The standard weighs in on performance durability design models but does not provide advice. BS 6744 has positioned itself as the preferred choice of stainless steel standard in the UK and internationally. Main features of BS 6744.

The main features of interest to stakeholders include :

Metric bar sizes, area, mass by steel designation, and bend diameters

Stainless steels and their chemical composition classified for their properties of :

low magnetic permeability,

corrosion resistance to chloride ingress in concrete

corrosion resistance where the steel is exposed

Two stainless steel classifications – duplex and austenitic

Reference to surface quality and finish

Surface and rib geometry

Mechanical and physical property requirements, strengths and testing procedures

A test method for determining the corrosion resistance of stainless steel reinforcing in chloride contaminated concrete

Mandatory testing for detrimental metallurgical phases (duplex types) and intergranular corrosion (austenitic and duplex types)

A prescriptive-based guidance on the durability of reinforced concrete indicating the type of stainless for given exposure conditions

The standard discusses performance durability design models such as the fib Model Code; however, citing the need for more research it does not provide advice on these models

Guidance on magnetic properties, coefficients of thermal expansion and welding

A copy of the Standard can be obtained through the British Standards Institution.

Stainless Reinforcement Fabrication Standard

ANSI / CRSI – IPG4.1 : 2016

Standard Practice for Stainless Steel Reinforcing Bar Fabrication Facilities

IPG4.1 outlines the appropriate fabrication methods and procedures to fabricate stainless steel reinforcement in a manner that conforms to the standard accepted practices while ensuring that contamination of the steel with carbon steel is eliminated. Key fabrication methods.

Putting aside quality assurance responsibilities and personnel training components of the standard, those parts of IPG4.1 dealing with the fabrication side of the business include :

A material “accept/reject” criteria and treatment of non-conformities

Frequency of plant wide inspection for carbon contamination

Procedures regarding the quality of material upon receipt

Methods, procedures and special protection materials and devices used throughout the operation in handling and storing the material

Special procedures and protection systems for storing material outdoors

Methods, procedures and special protection materials and devices used throughout the plant in the bending and shearing operations

Special procedures and protection systems for shipping material

A copy of the Standard can be obtained through the CRSI.

Structural Welding Code – Stainless Steel

AWS D1.6

This American Welding Society (AWS) code establishes the requirements for welding stainless steel using the gas metal, shielded metal, flux cored, and submerged arc welding processes, including stud welding. The code covers design, fabrication, qualification and prequalification of procedures welding personnel qualification, and inspection. It is ANSI approved. The code is available online.

Different Stainless Steel Standard Designation Names

AASHTO LFRD Bridge Design Specifications

CSA S6, Canadian Highway Bridge Design Code

ASTM A1064: Standard Specification for Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete

ASTM A276: Standard Specification for Stainless Steel Bars and Shapes

ACI 117, Standard Tolerances for Concrete Construction and Materials

CSA A23.1, Concrete Materials and Methods of Concrete Construction