Why use it? here’s the simple answer

It is proven to provide superior long term durability.

Therefore, USE IT to keep the roads open and save money relative to other options.

That’s it!

WHY? : Because it Works!

> 85 yearS of proven Service Life

> independent UNBIASED research concludes …

SSR Best Material at Resisting Corrosion

ensuring superior durability

Powerful chemistry, no coatings, virtually no carbon

WHY? : Because it is Cost Effective!

Operating Cost Savings makes SSR the

LOWEST Cost Option

stainless Steel solves the corrosion problem

Owners want their structural systems to perform better over longer periods of time …

in environmental conditions which will be excessively harsh …

… for marginally corrosion resistant reinforcement options.

The viability of an entire structure can be significantly compromised by corrosion.

In a recent DOT study of a 100-year bridge deck service life, no repairs were planned for the option with stainless steel rebar.

For all other coated and low alloy corrosion resistant bar options, two major repairs were planned to achieve a 100-year service life.

This is a strong admission from a major State that stainless solves the corrosion problem.

It also points out the vast difference in the corrosion resistance and durability between stainless steel and other options.

Stainless steel rebar solves the problem of premature reconstruction of structures subject to corrosion for generations.

Owners using SSR will be rewarded with longer term, more sustainable durable structures relative to those built with other rebar products.

This sustainable advantage is what makes SSR the least cost solution for structures facing chloride attack.

Why use Stainless – The Rationale : Cost Savings and Open Roads

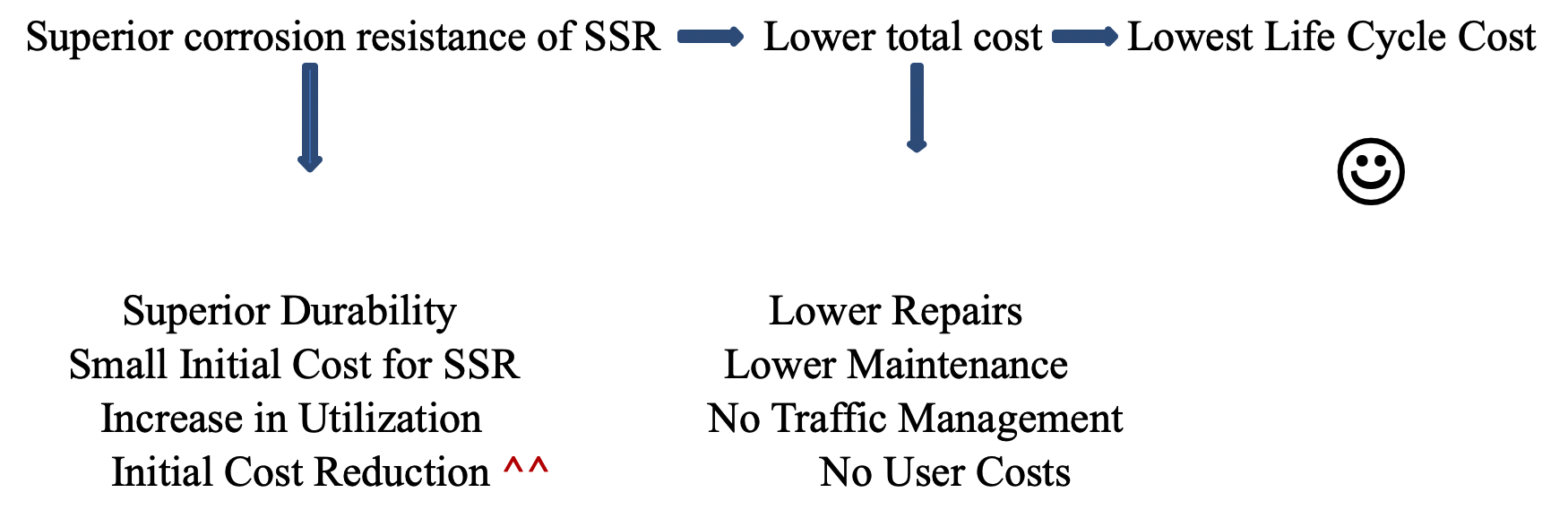

The Rationale is Simple -- for a structure under chloride or chemical attack the use of SSR will save the Owner money over the service life of the structure compared to the use other reinforcement bars.

How? SSR’s chemistry is specifically formulated to resist corrosion which increases the durability of concrete,

… which reduces repairs and maintenance costs,

…… while extending the service life beyond that achievable with other available reinforcement materials, and

……… the utilization rate of these structures increases as repair programs are drastically reduced in terms of time and intensity.

Taking all these factors into consideration, the Life Cycle Cost with structures using SSR is the least of any comparable alternative.

It is not rationale to think that spending less now on low cost, inadequate materials will somehow allow planners to escape the longer term repair cost consequences.

Cost Competitiveness

The cost of SSR is competitive with other lesser resistant materials, in fact costs have decreased in real terms. Any premium is worth it because Stainless Works. Link to Read more

The cost of fabricated stainless steel reinforcement delivered to the field relative to other corrosion resistant bar is very competitive having declined in real terms by 10% over the last 5 years while competitor’s products have apparently increased. The small premium for stainless is justified by the benefits it delivers.

Superior Chemistry = Superior Corrosion Resistance

SSR is alloyed specifically to provide superior corrosion resistance. Link to Read more

Chemistry matters and it is the alloy formulation especially designed to effectively resist chlorides which differentiates stainless from other products proven to be inadequate to provide 100 year service life.

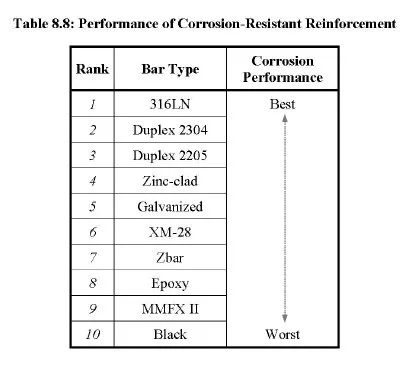

Stainless steel rebar has been extensively tested by publicly and privately funded entities for corrosion resistance in comparative studies against other rebar products and consistently ranks substantially ahead -- in fact orders of magnitude better than other rebar products. Click here for Research (see the 2 studies below).

Superior Corrosion Resistance Performance : Laboratory Research

Consistently the corrosion resistance research performed over many decades by various independent* bodies concluded that stainless steel rebar is vastly superior to other products. SSIG does not pay for research. Firms representing lesser corrosion resistant rebar products pay for research which is not independent, but rather self-serving. Click here for two examples of independent corrosion resistant studies.

The stainless steel industry does not pay for research into the corrosion resistance, durability and the long term cost effectiveness of its material. The superiority of this material as indicted by these three critical criteria are known and accepted by all science based, unbiased professionals. Beware of statements to the contrary.

Web designer : Access these two studies via a link :Both are in file : 5.5-SSIG Website, Resources, Corrosion Resistant Research.docx”Indiana DOT, Purdue University - Increasing Bridge Deck Service LifeJoint Transportation Research ProgramIndiana DOT and Purdue UniversityFHWA/IN/JTRP-2014/16Robert Frosch, Samuel Labi, Chungwook SimDecember 2014Increasing Bridge Deck Service Life : Volume I – Technical Evaluation

The research paper conducted for Indiana DOT points out the failings of epoxy-coated reinforcement and the potential for other corrosion resistant materials to provide improved performance. Volume I of the study examined the efficacy from a technical perspective of using alternative materials in a bridge deck. A primary part of the research focused on ranking reinforcement materials on the basis of corrosion resistance. Based on a thorough evaluation of corrosion measurements and a visual examination of the results of specimens exposed to chlorides in un-cracked and cracked concrete, the stainless steel reinforcement specimens outperformed the coated and uncoated rebar samples. A link to the study is available HERE.

Another example is a study by the University of Waterloo under the guidance of Dr. Carolyn Hansson

Ministry of Transportation of Ontario (MTO), University of Waterloo, - Increasing Bridge Deck Service Life

MTO Research

University of WaterIoo, Ontario, Canada

Colin Van Niejenhuis, Thesis, Dr. Carolyn Hansson, Professor

2015

The Case for Stainless Steel Reinforcing Bars

A comprehensive study was conducted for the Ministry of Transportation of Ontario (2015).

Both an electrochemical and comparative visual analysis of the corrosion resistance of steel rebar was undertaken. In the study, stainless steel rebar was compared to galvanized, MMFX and black rebar. Rebar was cast in sound and cracked concrete and subjected to various chloride ponding solutions. The rebar samples were then extracted from the tombstones and examined for visible corrosion. A combined ranking was developed on the basis of these two analyses.

All stainless bars had superior performance relative to galvanized and MMFX .

Other such independent research is available can be found HERE.

Link to “Resources” Section on Corrosion Resistance Research, the file is : “5.5-SSIG Website, Resources, Corrosion Resistant Research.docx”

The study concluded that the galvanized and MMFX bars were 10 to 100 times more corrosive than the stainless specimens.

Increased Concrete Durability

Stainless protects the concrete from deterioration ensuring long term durability. Link to Read more

In the case of other corrosion resistant rebar, once the chlorides reach the steel and rust forms, the expansion forces burst the concrete causing cracking and spalling requiring major structural repairs.

Stainless steel reinforcement with its specially alloyed steel types allowing for much higher chloride threshold values for corrosion initiation fundamentally ensures that the concrete will be more durable into the long term.

Service Life Extension

Increased durability extends the service life. Link to Read more

The increased durability which SSR affords structures subject to chloride attack results in an extended service life relative to that provided by other types of reinforcement. The benefit of a small additional upfront investment by specifying SSR is a long lasting structure.

Lower Operating and User Costs for Durable Structures

Operating costs are reduced.

Link to Read moreThe direct benefit from more durable structures is a drastic reduction in maintenance and major repairs to structures, the cost of traffic management during repairs and the macro-economic benefit of reducing the cost of delays to users.

Dramatic Reduction in LLC

^^ Link to Section : “The Potential to Reduce Initial Material Cost”Chemistry targeted to provide superior corrosion resistance results in the lowest life cycle cost.

Link to Read more. There is a logical cause and effect relationship which flows from superior corrosion resistance to an increase in concrete durability and ultimately results in lower total life cycle cost.

The superior stainless steel rebar product may add to the initial project cost, but the total incremental project cost is normally quite small compared to the benefit of avoiding the higher ongoing repair and maintenance costs.

Life Cycle Cost Studies References to Life Cycle Cost studies such as by the Indiana DOT and New York State DOT and others are provided here (see file 5.4-SSIG Website, Resources, Life Cycle Cost Studies, Service Life.docx)

THE BENEFITS OF USING STAINLESS STEEL VASTLY EXCEED THE INCREMENTAL COST ASSOCIATED WITH THIS MATERIAL

Use Stainless for its chemistry

The chromium forms a passive layer on the metal surface which prevents corrosion. This layer is only effective with a chromium content of the rebar at 10.5 % and above . Link to Read more

Stainless steel resists corrosion by forming a thin, invisible tightly adhering layer of chromium oxide on its surface when exposed to oxygen. This passive layer, composed of chromium oxides on the surface which bonds with the underlying metal acting as a barrier, prevents corrosion from occurring.

The passive layer acts as a barrier, preventing water, oxygen, and other corrosive agents from reaching the underlying metal and causing corrosion.

The chromium content in stainless steel is crucial for this protective film to form. A minimum level of 10.5% chromium is required to effectively form the passive film and resist corrosion. Lower levels of chromium than this threshold of 10.5% are ineffective in warding off corrosion much beyond black bar therefore in extending service life.

Stainless steel rebar alloys have roughly twice this minimum threshold of chromium needed to maintain its passivity and provide and vastly superior service life.

The proof is here.

Click to Progreso https://bonavista-rebarassociation.squarespace.com/why-stainless#progresoOther Alloying Elements:

While chromium is the primary element for corrosion resistance, other elements like nickel, molybdenum, and manganese can be added to enhance specific corrosion properties.

Unique Features and Beneficial Material Properties

Comparable Design Concepts (read more, link to text below)

The modulus of elasticity is within 3% of that of conventional mild steel and as such the design concepts are similar.

The bond strength with concrete is the same as black bar.

The development length and lap splice length is the same as black bar, while coated products require 30% more development length.

Backed by an ASTM Standard (read more, link to text below)

Stainless steel rebar is manufactured to the standard ASTM A955.

Same bar sizes as Conventional Steel (read more, link to text below)

Stainless is available in the same bar sizes as conventional reinforcing bar steel. Click to the file “Properties of Stainless Steel Rebar”

High Strength Steel (read more, link to text below)

Stainless steel is readily available in Grade 80 material. The yield is calculated as 0.2% offset.

Exceptional elongation-Ductility – Exceeds all other rebar material (read more, link to text below)

The ductility of this material vastly surpasses that of all other rebar material as mill level elongations are 20% for Grades 60 and 75, and 16% for Grade 80.

The ductility is best portrayed on the stress-strain curves shown here (see file “Stress-Strain Curve XM-28 GR75”) for the most commonly used A955 alloys.

Mandatory Corrosion resistance test in ASTM A955 (read more, link to text below)

The standard A955 requires that an alloy pass the corrosion resistance test in the Annex to qualify as a stainless steel material and inclusion in the Standard.

Other commercially available rebar materials claim corrosion resistance, however these products do not pass the A955 qualification test.

Material is Readily Available (read more, link to text below)

Stainless steel rebar materials and accessories are available from the SSIG members. Link to Read more

The SSIG members as a group are dedicated to providing you with highest quality of stainless steel rebar. The North American Stainless mill in Kentucky can supply material in coil or straightened bar lengths, while the three fabricators who keep an active and well stocked inventory of all the common types and sizes of stainless steel reinforcing bar, can supply rebar made to the exact dimensional requirements, and shipped anywhere in the U.S.A. and in Canada.

Stainless steel wire mesh and couplers are also stock items ready to be shipped.

Lead time is minimized given the large inventory of products held on hand as stock items by the fabricators.

Lower Environmental Footprint

Stainless steel significantly extends the service life without major repair or maintenance beyond 100 years, which has the effect of lowering the environmental impact and disruption of unnecessary rehabilitation projects well beyond that which otherwise be the case.

The SSIG members as a group are dedicated to providing you with highest quality of stainless steel rebar. The North American Stainless mill in Kentucky can supply material in coil or straightened bar lengths, while the three fabricators who keep an active and well stocked inventory of all the common types and sizes of stainless steel reinforcing bar, can supply rebar made to the exact dimensional requirements, and shipped anywhere in the U.S.A. and in Canada.

Stainless steel wire mesh and couplers are also stock items ready to be shipped.

Lead time is minimized given the large inventory of products held on hand as stock items by the fabricators.

Fabrication and Installation – no worries

The cutting and bending fabrication operations and the equipment required to fabricate this material are the same as for conventional black carbon steel reinforcing bars. There is however, the need to avoid carbon contamination throughout the plant. A stainless steel fabrication standard can be found here (click to file 5.6-SSIG Website, Resources, Standards.docx).

Stainless steel is a fully weldable product. The filed installation procedures follow those for conventional steel reinforcement.

Why Use Stainless?

The Potential to Reduce Initial Material Costs

There are a number of potential initial construction cost savings opportunities attributable singularly to the use of stainless steel rebar.

Some of these potential cost saving opportunities include :

Concrete Cover Reduction

Historically, engineers used an increase in concrete cover as a defense mechanism against chloride ingress and ultimately to protect black steel from rusting. As stainless steel self protects, there are substantial savings to be made by reducing excess concrete cover intended for black steel but essentially redundant with the use of stainless. In new structures, less cover reduces the dead load which lightens the design load on supporting members; hence, a savings in concrete costs.

High Strength Steel

As the Grade 80 stainless steel rebar is high strength steel, there is the potential for Owners to reduce the amount of rebar steel by mandating their design engineers to design bridge structures using this higher yield point. (The Minnesota DOT has reported a 15% saving by embracing this practice).

Deck Overlays, Pavings, Membranes, Deck Sealants, Concrete Additives

The “belt and suspenders” philosophy of protection duplication is unnecessary with stainless. This high performance rebar product is the only protection system required. Secondary systems are potentially a waste of money.

Development length

Design concepts follow that of conventional black rebar. The development length and splice length is the same as black bar compared to coated products which require 30% more development.

Additional Load Carrying Capacity

For existing structures rehabilitated with SSR, this weight reduction due to less cover enhances the efficiency of the structure by increasing the live load carrying capacity.

Avoidance of Coating Repairs

There are no repair costs associated with damaged coatings due to poor handling in the shop or at the job site.

Why use Stainless : Decades of Evidence Matters!

Actual Field Record of Success

85 years of Positive Field Performance of Stainless Steel in Salt Water

The world’s longest pier (now 6 KM long) built in the Caribbean Sea in 1937-1941 still in use today.

The port city of Progreso, in the Mexican state of Yucatán, boasts of the longest pier in the world. The pier is also the first concrete structure in the world constructed between 1937 and 1941 with stainless steel reinforcement. Despite the relatively poor grade of concrete used, the pier has withstood the harsh marine environment and has been in continuous service for over 75 years without any major repair or routine maintenance activities.

CLICK HERE to view the life cycle analysis of Progreso Pier by the Nickel Institute.

We need to find this study and set a link.Progreso Pier: Gulf of Mexico

The port city of Progreso, in the Mexican state of Yucatán, boasts of the longest pier in the world.

Aerial view of the 6km long Progreso Pier

GUIDANCE ON WHERE TO USE STAINLESS

>Where to use the Corrosion resistance properties : guidance

Stainless steel is formulated to resist corrosion. The combination of the alloying elements of chromium, molybdenum and nitrogen in the different compositions of stainless steel increases the resistance to the various types of metal corrosion.

The performance of any given type of stainless steel reinforcement will depend on a number of factors.

severity of the service environment,

expected chloride exposure,

pH of the concrete,

the quality of the downstream maintenance program pertaining to the facility or structure, and

any prior contamination for existing structures.

The advantage of the availability of different types of stainless steel with varying compositions and therefore performance is that it allows specifiers/designers to match the chemistry required for the particular service condition.

Pitting resistance equivalent number: PREN

In order to compare on a relative basis the corrosion resistance of the various types of stainless steel, a predictive measurement of a stainless steel's resistance has been developed.

It’s called the “Pitting Resistance Equivalent Number” or PREN. Basically, a higher PREN-value indicates more resistance of the stainless steel to corrosion. PREN numbers are a practical and useful tool for ranking and comparing the different types of alloys.

The PREN is based on the chemical composition and is calculated for the austenitic and duplex steels as follows :

For austenitic steels the predictive expression is :

PREN = %Chromium + 3.3 x %Molybdenum + 16 x %Nitrogen

For duplex steels the predictive expression is :

PREN = %Chromium + 3.3 x %Molybdenum + 30 x %Nitrogen

The PREN values for the commonly used stainless steels in ASTM A955 are as indicated in Table 1.

Table 1: PREN Values

Click to view larger

Within the group of commonly used stainless steel rebar products, an average ranking based on the published research of corrosion resistance in descending order is as follows :

316ln and 2205

2304

24100

Link to Resources Tab, the section : “Where to Use Stainless” for more information {This is the NI’s SSR website Section on “Risk of Corrosion”}WHERE TO USE THE LOW TEMPERATURE PROPERTIES

Performance Guidance in Temperature Extremes

Austenitic types of stainless steels have excellent toughness at the low temperatures prevalent in cryogenic applications such as LNG applications.

Duplex types of stainless steel are suitable for applications for temperatures as low as -50°C.

WHERE TO USE THE LOW MAGNETIC PERMEABILITY PROPERTIES

Performance Guidance for Magnetic Permeability

In applications requiring a non-ferromagnetic response typified by a very low or negligible response to electromagnetic fields, austenitic stainless steels are suitable. A limit is then usually specified on the relative magnetic permeability of the steel.

Austenitic steels can be classed as 'paramagnetic' with a relative permeability approaching 1.0. This low permeability enables austenitic steels to be used where 'non-magnetic' materials are required.

Concrete reinforcing bars for MRI’s, radar installations, naval facilities, Light Rail Transit -- essentially where ever rebar may be in close proximity to sensitive electronics.

The Benefits

The primary advantage in using SSR is the cost reducing effect attributable to its durability.

The highly alloyed chemistry of SSR used in concrete structures subjected to corrosive service conditions significantly increases the ability of stainless steel bars to resist corrosion. The significant increase in durability relative to all other conventional reinforcement products extends the service life of these structures while drastically reducing Owners’ operating costs.

The set of unique SSR mechanical properties including its high strength, superior ductility, excellent fire resistance, maintaining a high level of strength at extreme temperatures, etc. can be leveraged by the Owner to provide further cost reducing benefits.

TOP 10 BENEFITS OF STAINLESS STEEL

Superior Corrosion resistance

Long term Durability

Repair Cost Savings

Open Roads – macroeconomic benefits

Low Life Cycle Cost

savings on Concrete mix, deck protection systems

Strength

ductility

Recycleability

conventional bar sizes and development length

Final Word: It May Cost more but it Works!

The Owner has a choice of many types of rebar at various quality levels and prices points which mirrors our consumer society.

One can always pay less for a product but to expect the same or better performance at a lower price is not realistic. Stainless steel rebar delivers unmatched quality and benefits as measured by superior corrosion resistance, concrete durability, a significantly longer service life without repair than with other rebar material, cost avoidance opportunities, and increased structure uptime. And ultimately, the least life cycle cost.

Stainless steel works, and more than pays for its cost.

The raw material may cost a bit more but it works!

It’s Steel

Other non-steel bars made of composite materials are appearing on the market. These bars have different mechanical properties relative to steel notably that the allowable design strength is severely reduced due this material’s characteristic to lose strength over time, the strength in the transverse direction is very limited and the product is susceptible to degradation in humid conditions which calls into question the durability of this material.