Indiana DOT and Purdue University

Joint Transportation Research Program

Indiana DOT and Purdue University

FHWA/IN/JTRP-2014/17

Samuel Labi, Robert Frosch, et al

December 2014

Increasing Bridge Deck Service Life : Volume II – Economic Evaluation

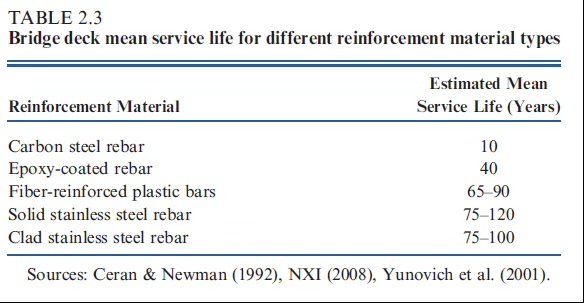

The research paper conducted for Indiana DOT points out the failings of epoxy-coated reinforcement and the potential for other corrosion resistant materials to provide improved performance and extended service life (see table below from the Indiana/Purdue study). The study developed a framework for evaluating the life cycle cost of structures using different types of reinforcing materials. Only stainless steel and epoxy coated are considered viable options, with MMFX and zinc coated bars viewed as not feasible as long term options. Stainless steel reinforcement was evaluated as a superior alternative relative to epoxy coated bars both on a durability and long term cost effectiveness (life cycle cost) basis. A link to the study is available HERE.

New York State DOT

New York State DOT, Carpenter Technology Corporation

August 2007

Improving Tomorrow’s Infrastructure : Extending the Life of Concrete Structures with Solid Stainless Steel Reinforcing Bar

The report states that advances in concrete technology have provided materials which can last at least 100 years but that the service life is limited by the reinforcing material. Increasing the life of the reinforcing will directly extend the life of a structure. Projections by transportation agencies show that the use of solid stainless steel reinforcing bar in bridge decks dramatically increases the life of the deck. The use of solid stainless steel reinforcing bar has the effect of reducing downstream deck rehabilitation costs; this offsets the initial higher cost of the stainless resulting in a lower life cycle cost (LCC) of the structure than would be the case without stainless steel. The authors report more than a 20% reduction in LCC for a bridge deck with solid stainless steel reinforcing bar and about at 10% saving for a new bridge. At the time the report was published in 2007, the authors reported that in most cases the stainless steel adds less than 1.5% to the total structure cost. On the whole, due to competitive forces in the stainless steel reinforcement industry, currently it is estimated that the total structure cost would be lower than 1.5%. The report also considered the impact of reducing the minimum concrete cover required with stainless steel relative to that required to protect conventional rebar from corrosion. The DOT concluded that with the use of stainless steel reinforcing bar, concrete cover can be reduced cutting concrete costs and structure weight. The savings help offset the cost of the stainless steel. The NY DOT design manual subsequent to this report mandates a reduction of 1” in concrete cover exclusively with the use of stainless steel reinforcement. See a summary of the report.

Life Cycle Cost of Building and Rehabilitating a Bridge Deck over a 100 Year Period – New York State (1)

(1) Referenced from “Improving Tomorrow’s Infrastructure : Extending the Life of Concrete Structures with Solid Stainless Steel Reinforcing Bar”. August 2007.

(2) In the analysis of the LCC of a deck using various types of rebar, all costs were indexed as percentages relative to the cost of building a deck using epoxy coated rebar.

(3) The figures presented also apply to stainless steel type UNS S32304.

A summary of the key points of the report is as follows :

The features, properties and performance of the various types of reinforcing materials are reviewed

The types of reinforcing materials are screened for use in economic cost comparisons of structures built with these different types of bars

A comparison of the initial cost and 100 year life-cycle cost (LCC) was conducted of a range of structures built using different types of reinforcement material

Table 1 summarizes the LCC of new bridge decks with various types of deck reinforcing; those constructed with stainless steel reinforcement were the least cost alternative -- 21% less than the epoxy coated and galvanized options

Table 2 summarizes the LCC of new bridges with various types of deck reinforcing factoring in cost savings attributable to a reduction in concrete cover and a reduction in dead load; stainless steel reinforcement were the least cost alternative -- 9% less than the epoxy coated and galvanized options

The initial cost taking into account the concrete cover savings and the effects of less dead load on the superstructure resulted in an initial cost increase for new bridges of only 1.4%

Table 3 takes into account savings in foundation costs attributable to dead load reductions in Table 2 resulting in an initial cost increase for new bridges with stainless steel of less than 1%

Examples are provided of bridge rehabilitations in New York where the use of stainless after taking into account design efficiencies was cost neutral

A copy of the Report is available here.New York State DOT

New York State DOT, Carpenter Technology Corporation

August 2007

Use of Advanced Materials to Extend Bridge Life and Reduce Initial Cost

This paper continues the work by New York State DOT and Carpenter Technology from the previous study “Improving Tomorrow’s Infrastructure”. The study provides an overview of the previous uses of solid stainless steel rebar and an introduction to new lower cost types of stainless steel alloys and their performance. It notes that in seismic testing by MCEER at the University of Buffalo the stainless steel rebar samples out performed conventional steel and MMFX. The paper summarizes the life cycle cost analysis for new bridges using various types of reinforcement while taking into account cost savings potential of reduced concrete cover, lighter superstructure components and foundation savings. It also provides details of the net savings that were incurred on three projects in New York City due to the use of stainless steel rebar. See a summary of the Report.

A summary of the key points of the Report is as follows :

The report points to the field success of using stainless steel rebar in the context of the pier in Progreso, Mexico and numerous other projects in the U.S.

Tests by the FHWA and various states showing that stainless steel will last at least 100 years are referenced

The corrosion resistance performance of what were at the time newer alloys, i.e. S24100, S32304 and S32101, are explained

The report notes the positive performance in seismic testing of stainless alloys

The impact on life cycle cost of cost reduction benefits of design improvements such as concrete cover reduction (the concrete cost and the dead load reduction), main member size reduction, foundations are presented

A detailed analysis of the savings impacts of using stainless steel rebar on three New York City projects is presented indicating the potential for a reduced total project cost attributable to the use of stainless

A copy of the Report is available here.

VDOT Implementation of Corrosion Resistant Reinforcement

ACI 123 Forum

Presentation : What is the Current State of Epoxy Coated Reinforcing Steel?

Michael Sprinkel P.E., Stephen Sharp Ph.D., P.E., VDOT

April 3, 2011

Stainless has the Lowest Life Cycle Cost

The presentation explains VDOT’s reasoning for eliminating epoxy coated rebar and validates its movement to stainless steel reinforcement indicating that stainless provides the least life cycle cost.

The presentation highlights VDOT’s observations that the coating of epoxy coated rebar deteriorates with time and cracks with age, loses adhesion with the bar leading to severe corrosion, section loss and failure. The DOT discontinued the use of epoxy coated and galvanized bars and switched to stainless steel rebar. By avoiding the unnecessary bridge maintenance repair costs associated with other rebar options such as epoxy coated and MMFX reinforcement over a 90 year life, the life cycle cost of the stainless steel option was substantially cheaper (over 40%) than MMFX and epoxy coated options.

The presentation is available here.

Corrosion-Resistant Reinforcing Steels

Kansas DOT, National Science Foundation, South Dakota DOT, FHWA, et al

David Darwin, JoAnn Browning, Javier Balma, et al

2002 Concrete Bridge Conference

Stainless has Lowest Life Cycle Cost

The research paper studied the corrosion rates of a number of types of steel reinforcement including epoxy coated, MMFX and stainless steel. The research concludes that stainless steel corrodes at such an exceptionally low rate that it alone can provide repair free service over a period of 75 years. The use of stainless steel would result in the least life cycle cost with the cost of MMFX and epoxy coated being 70% and 90% higher respectively.

The presentation is available here.

The World’s Longest Pier : A Case Study on Stainless Steel Rebar

The International Journal of Life Cycle Assessment

ISSN 0948-3349

Mark Mistry, Christoph Koffler, Sophia Wong

March 22, 2016

LCA and LCC of the World’s Longest Pier : A Case Study on Nickel-Containing Stainless Steel Rebar

A 2.1 kilometer concrete pier was put into service in 1941 in the port city of Progreso, Mexico in the Yucatan Peninsula. It was built with nickel containing stainless steel rebar (type 304) and is still in service today. The aim of the study was to understand the economic implications of selecting stainless steel reinforcement. A comparison was made of the actual repair history of the Progreso Pier and modeled a similar Pier but with carbon steel. The despite the modelled lower initial capital cost of a carbon steel reinforced structure, the total life-time cost would have been 44% higher than the actual Progreso Pier due to more frequent maintenance events and reduced service life necessitating reconstruction of the Pier.

The presentation is available here.

Pier in Progreso, Mexico : Inspection Report

RAMBOLL Consulting Engineers and Planners

Arminox Stainless

March 1999

Pier in Progreso, Mexico : Inspection Report

Evaluation of the Stainless Steel Reinforcement

The report presents the results of an inspection of the concrete pier in the port city of Progreso, Yucatan, Mexico which had been in service as of 1941. RAMBOLL assessed the general condition of the concrete pier and the stainless steel reinforcement. They concluded in 1999 that after nearly 60 years of service, despite the saline and subtropical environment combined with poor quality concrete, no significant corrosion problems were observed for the AISI 304 type of stainless steel.

The presentation is available here.

Comparative Rebar Costs and Service Lives

Initial Cost versus Long Term Benefit -- NY State DOT

The benefit of using stainless steel reinforcement as opposed to other less resistant reinforcement such as epoxy coated bars is clearly evident from the extensive body of life cycle cost analysis. Despite this reality, there remains a tendency to focus on initial cost as the main decision variable in building more durable structures. To that point, it is evident that the incremental initial construction cost of using a more resistant stainless steel material is not significant (reference Schnell, Bergmann). The initial cost can be further reduced by relaxing some of the construction strategies used to protect non-corrosion resistant or lesser corrosion resistant reinforcement such as :

deck sealants,

rust inhibitors,

excess concrete cover reduction with the benefit of less dead load, and

eliminating the cost of handling coated bars and coating repair in the field.

Putting aside the potential for initial cost savings associated with the use of stainless steel reinforcement, the fact remains that the stainless steel has a small effect on the overall project cost. Stainless steel reinforcement is only used in the critical exposure zones of a structure. Hence, its use represents a very small portion of the overall rebar tonnage on a structure and by extension the impact on the total project cost is small. Furthermore, in the New York State DOT reference (“Use of Advanced Materials to Extend Bridge Life and Reduce Initial Cost”), cases were presented where structures with stainless steel were the least cost as built.

It is important in making the choice between superior corrosion resistant materials and less durable options to focus on the extended service life and long term cost reduction benefits which material durability, such as stainless steel reinforcement, can provide to the Owner.

New York State Department of Transportation, Bridge Manual 2019

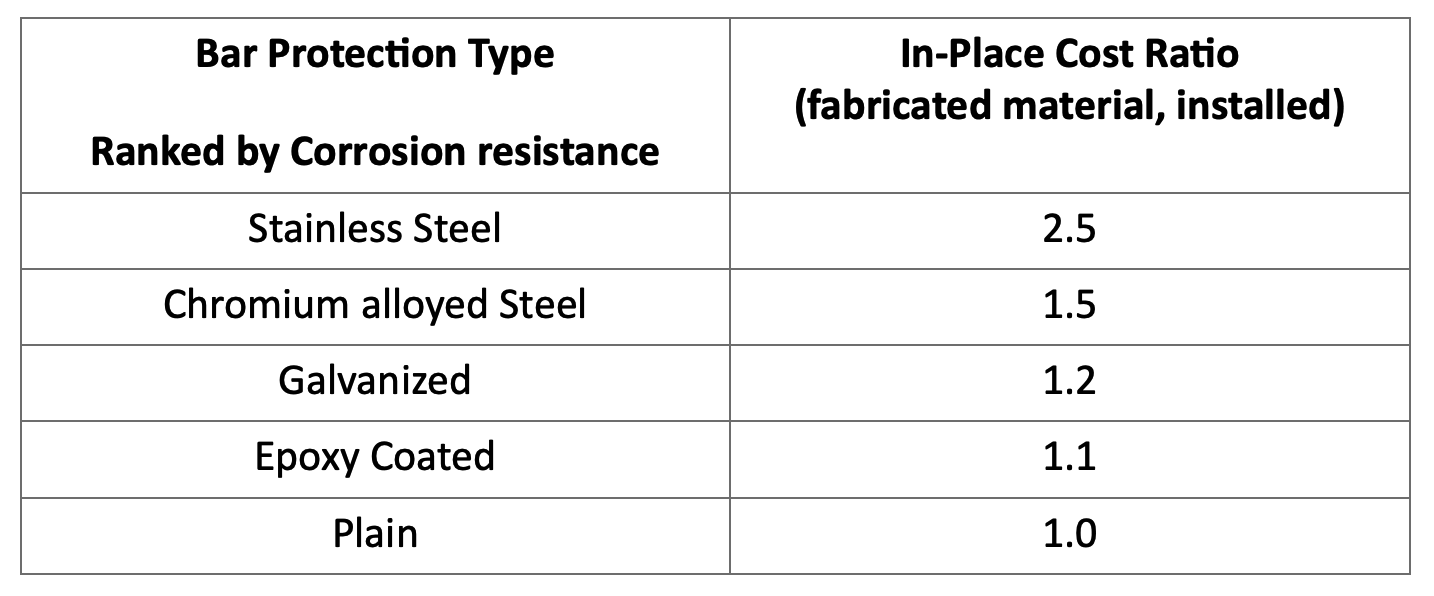

In the Bridge Manual, Table 15-2 compares approximate current cost ratio estimates for reinforcing bars capturing the cost at the time of publication (2019) of strictly the rebar material, fabrication and installation component of the overall project cost using plain reinforcing bars as a base. As mentioned in the Manual, prices change over time and vary by geographic location. Designers should check current prices when cost is a consideration. It is worth noting that rebar costs represent a small portion of the total initial project cost.

Table 15-2 Approximate Reinforcement Cost Comparison

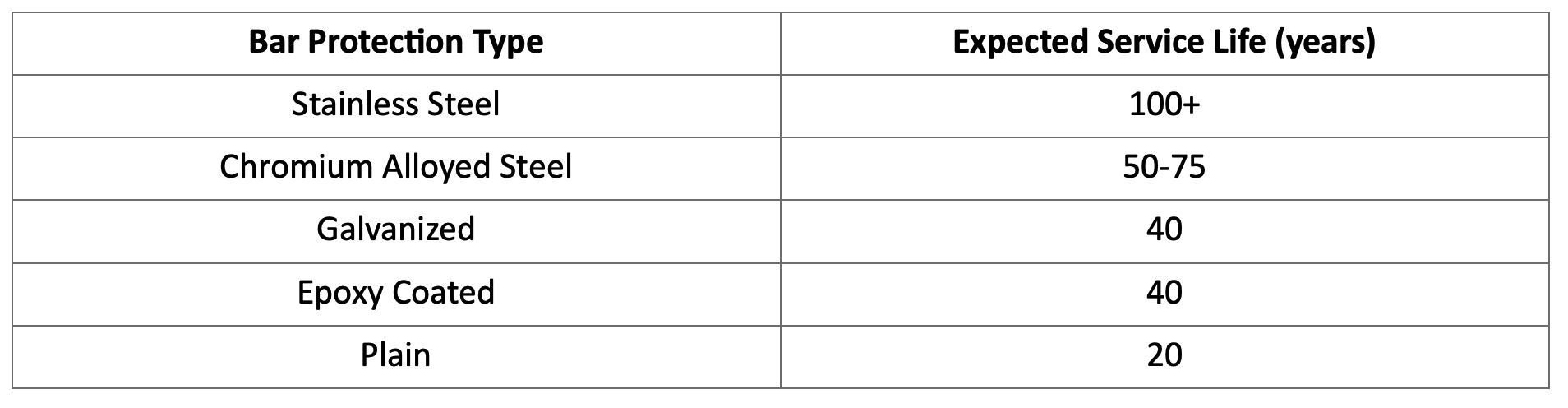

Table 15-3 of the Bridge Manual illustrates the expected service life for the different types of reinforcing bars in conventional concrete with standard cover exposed to a corrosive environment. It is evident that stainless steel provides a significant benefit of additional service life in contrast to other types of rebar.

Table 15-3 Expected Service Life

Indiana DOT and Purdue University

As guidance to Owners, specifiers and designers in their assessments of long term cost effectiveness of structures, the Joint Indiana DOT and Purdue University research paper referenced on this website suggested estimates of the mean cost of stainless steel and epoxy-coated reinforcement in North America and the service lives of structures using each of these materials. Current reinforcement costs can be obtained from rebar suppliers.

Source : Indiana DOT and Purdue – Joint Transportation Research Program

(1) Cost to the DOT/Owner

(2) Adjusted in 2014 to current market value by researcher. Actual current “Mean Cost” to the Owner of stainless steel relative to epoxy coated is 2 to 2.5 times higher.