VDOT - Linear Cracking in Bridge Decks

VTRC 18-R13

Soundar Balakumaran, Richard Weyers, Michael Brown

March 2018

Concrete cracking in bridge decks remains an important issue relative to deck durability. The presence of cracks affects the service life significantly. The study concludes that the time to corrosion initiation for stainless steel reinforcement was estimated to be in excess of 150 years which is 5 times longer than MMFX. Virginia DOT engineers conclude that the service life of decks built with VDOT’s current concrete mixture and the use of stainless steel reinforcement can be extended to 150 years. The study is available on the VTRC website at http://www.virginiadot.org/vtrc/main/online_reports/pdf/18-r13.pdf

VDOT - Corrosion Propagation Characteristics of Metallic Bars

VTRC 07-CR9, February 2007

John Scully, Ph.D, Michael Hurley, Ph.D

Investigation of the Corrosion Propagation Characteristics of New Metallic Reinforcing Bars

The threshold chloride concentrations (thresholds) and corrosion propagation were investigated for solid stainless steel 316LN, a cladded version of 316, 2101 LDX stainless steel and uncoated types of carbon rebar including MMFX.

The study concluded that the total product life cycle of solid stainless steel reinforcement material is well over 100 years. In terms of alloy 316LN (UNS S31653), initiation of chloride induced corrosion will be unlikely in reasonably good concrete. If initiation does occur, it would be difficult to sustain propagation and any spalling damage would be limited. The study recommends the use of stainless steel as a low corrosion related maintenance option for critical applications. MMFX is seen as possibly inducing concrete damage similar to the case of carbon steel. The study is available on the VTRC website at www.virginiadot.org/vtrc/main/online_reports/pdf/07-cr9.pdf

Indiana DOT, Purdue University - Increasing Bridge Deck Service Life

Joint Transportation Research Program

Indiana DOT and Purdue University

FHWA/IN/JTRP-2014/16

Robert Frosch, Samuel Labi, Chungwook Sim

December 2014

Increasing Bridge Deck Service Life : Volume I – Technical Evaluation

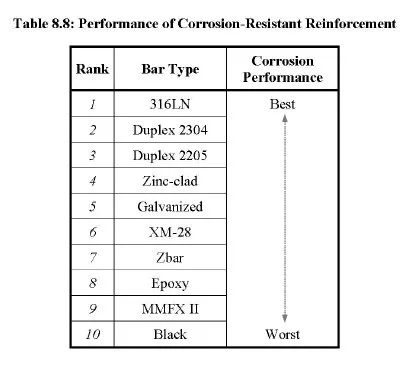

The research paper conducted for Indiana DOT points out the failings of epoxy-coated reinforcement and the potential for other corrosion resistant materials to provide improved performance. Volume I of the study examined the efficacy from a technical perspective of using alternative materials in a bridge deck. A primary part of the research focused on ranking reinforcement materials on the basis of corrosion resistance. Based on an a thorough evaluation of corrosion measurements and a visual examination of the results of specimens exposed to chlorides in un-cracked and cracked concrete, the stainless steel reinforcement specimens outperformed the coated and uncoated rebar samples.

A link to the study is available HERE.

Corrosion Resistance of MMFX2 Steel Reinforcement in Structures

National Research Council Canada

Zhang, J.; Qian, S.; Baldock, B.

B-5329.2

April 2009

Evaluation of Corrosion Resistance of MMFX2 Steel Reinforcement used in concrete Structures

The study evaluated the performance of MMFX relative to carbon and stainless steel. While MMFX performed better than carbon steel, stainless steel reinforcement has much greater corrosion resistance with MMFX2 corroding at a rate 30 to 50 times higher than stainless. Galvanic coupling between MMFX2 and either carbon steel or MMFX2 induced a direct loss in mass of the anodic bar of 10%. The stainless steels had much greater resistance to pitting corrosion than did MMFX2; for two of the stainless types studied resistance to pitting was 25 to 30 times greater than for MMFX; the third, stainless type 2205, did not display pitting at a chloride level of 21%. The MMFX rebar performance results were not based on an “as produced” condition but rather on a preferential “sandblasted” condition which provides improved but skewed performance results.

The study is available here.

Corrosion Resistance of Stainless Steel, Galvanized and MMFX bars

National Research Council Canada

Zhang, J.; Qian, S.; Baldock, B.

B5334.2

November 2012

Evaluation of Corrosion Resistance of Stainless Steel, Galvanized and MMFX Reinforcement

The study evaluated the performance of stainless steel alloys 316LN, 2205, 304, 2304, 2101, XM-28 and galvanized reinforcement. Some testing was also conducted of MMFX. The superior ability of stainless steel to resist corrosion was evident from the test results as follows. The critical chloride threshold values of the family of stainless steels tested ranged from initiating corrosion at the 21% to 7% chloride level. The reported levels of about 0.5% and 1.3% respectively for galvanized and MMFX rebar are substantially lower. In concrete prisms premixed with chlorides, the stainless prisms displayed little or no surface cracking at 10% chloride level. In the galvanized prisms, concrete cracking was evident at 1.5% chloride loading.

The study is available here.

Southern Exposure and Cracked Beam Tests of 2205 Stainless Steel Bars

The University of Kansas Center for Research

Matthew O’Reilly, David Darwin

February 2014

Southern Exposure and Cracked Beam Tests of Enduramet 2205 Stainless Steel Bars

The corrosion resistance of 2205 reinforcement was tested using the Southern Exposure and cracked beam tests, the latter in accordance with ASTM A955. The average corrosion rates for the steel specimens for both tests were practically zero with the rate never exceeding 0.1 µm/yr. The study is available here.

Critical Chloride Corrosion Threshold of Galvanized Reinforcing Bars

ACI materials Journal, V. 106, No. 2, March-April 2009

David Darwin, JoAnn Browning, Matthew O’Reilly, et al

According to the researchers, due to the mixed performance of galvanized reinforcement, the usefulness of zinc coatings is questioned. The study determined the critical chloride threshold of galvanized rebar as well as that of 316LN stainless steel. The test method involved ponding with a 15% sodium chloride solution. The conclusion of the study was that galvanized rebar will extend the life of bridge by only 3 years. The stainless steel did not exhibit any signs of corroding g during the test period.

The study is available here.

Comparative Corrosion Testing and Analysis

Wiss, Janney, Elstner

February 2008

The corrosion resistance of reinforcing bars as measured by critical chloride thresholds was tested using two standard test methods, ASTM G-109 and the 20-week Modified Southern Exposure, which are generally accepted by U.S. Federal and state DOT agencies. The bars tested included stainless steel type 304, MMFX and black carbon bar. The study reports that under both test programs the stainless steel bars did not corrode while both types of black bars exhibited early signs of corrosion especially in the Southern Exposure test.

The study is available here.

Corrosion Resistant Steel - Alloys for Reinforced Concrete, FHWA

FHWA-HRT-07-0-39, July 2007

W.H. Hartt

Summarized version of original report, sponsored by the CRSI

This research was precipitated by the uncertainties regarding the long term performance of epoxy coated reinforcement. The FHWA set out to investigate the properties of various steel alloys compared to black bars in concrete exposed to chlorides. A range of standard short term accelerated and long term exposure tests were performed measuring chloride threshold and corrosion rate. The study classified the corrosion resistant capability of bars into two groups as either “High Performers” which included exclusively stainless steel bars, namely 304, 316 and 2304 and “Improved Performers” relative to black bar. The study concluded that an intended service life of major reinforced concrete structures of 75 to 100 years can only confidently be achieved with the stainless steel “High Performer” reinforcements.

The study can be accessed on the CRSI website.

Performance of Epoxy Coated Rebar - Adhesion Loss : VDOT

VTRC 00-R16

Wioleta Pyé, Richard Weyers, Ryan Weyers, Michael Sprinkel, et al.

February 2000

Loss of adhesion due to chloride-free water penetration

Field Performance of Epoxy Coated Reinforcing Steel in Virginia Bridges Decks

In this study the corrosion protection performance of epoxy-coated reinforcing steel was evaluated in 18 bridge decks in Virginia. Adhesion loss of the epoxy coating to the steel surface was detected in all but one deck long before chlorides arrived at the level of the reinforcement. The loss of adhesion was related to chloride-free water penetrating the coating and accumulating at the metal/coating interface resulting in oxidation of the reinforcement. Once de-bonded, the coating will provide little additional service life.

The presentation is available here.

Failure of Epoxy Coated Rebar - VDOT

ACI 123 Forum

Presentation : What is the Current State of Epoxy Coated Reinforcing Steel?

Michael Sprinkel P.E., Stephen Sharp Ph.D., P.E., VDOT

April 3, 2011

VDOT Implementation of Corrosion Resistant Reinforcement – Failure of Epoxy Coated Rebar

The presentation explains VDOT’s reasoning for banning epoxy coated rebar and its movement to stainless steel reinforcement. The presentation highlights VDOT’s observations that the coating of epoxy coated rebar deteriorates with time and cracks with age, loses adhesion with the bar leading to severe corrosion, section loss and failure. The DOT discontinued the use of epoxy coated and galvanized bars and switched to stainless steel rebar.

The presentation is available here.

Corrosion-Resistant Reinforcing Steels

Kansas DOT, National Science Foundation, South Dakota DOT, FHWA, et al

David Darwin, JoAnn Browning, Javier Balma, et al

2002 Concrete Bridge Conference

Stainless Steel provides Superior Corrosion Resistance

The research paper studied the corrosion rates of a number of types of steel reinforcement including epoxy coated, MMFX and stainless steel. The research concludes that stainless steel corrodes at 1/50 to 1/250 the rate of carbon steel while MMFX corrodes at 1/3 to 2/3 the rate of carbon steel. Given these results, only stainless steel is viewed as a cost effective replacement for epoxy coated reinforcement.

The presentation is available here.

Duplex Stainless Steels & MMFX : Chloride Thresholds and LCC

Gerdau Ameristeel, Kansas DOT, South Dakota DOT, National Science Foundation

Jianxin Ji, David Darwin, JoAnn Browning

2005

Corrosion Resistance of Duplex Stainless Steel & MMFX : Chloride Thresholds and Life Cycle Cost

The 507 page report is a comprehensive comparative analysis of the corrosion resistance and cost effectiveness of using duplex stainless steels, MMFX and epoxy coated reinforcement. The report concluded bridge decks built with stainless steel would provide a service life in excess of 75 years without repair and in most cases had lower total life-cycle costs than those containing epoxy-coated or MMFX steel. In assessing the epoxy coated service life, the documented loss of adhesion between the epoxy and the steel was not included in the analysis.

The presentation is available here.

Galvanic Coupling between Carbon and Stainless Steel Reinforcements

National Research Council Canada

Qian, S.; Qu, D.; Coates, G.

NRCC-48162 2005

The study investigates the possibility of an increase in corrosion due to galvanic coupling effects by having stainless steel reinforcement in direct contact with carbon steel. A series of tests are performed in electrochemical cells and with specimens in concrete. The results clearly show that the galvanic coupling current of connecting stainless steel with corroding carbon is much less than the effect of connecting passive carbon to corroding carbon steel—the net effect is that connecting with stainless reduces the corrosion effect recorded between a mat of two carbon bars. Although there is an effect of coupling, in absolute terms the increase in corrosion attributable to coupling with stainless steel is relatively insignificant (about 1%) compared to the overall corrosion rate. Read more.

Details of the main findings of the study include the following :

The galvanic coupling current induced by stainless steel is much smaller than that induced by passive carbon steel when these two metals are coupled with corroding carbon steel.

The galvanic coupling current between corroding carbon and stainless steel is less than half of that between corroding carbon and passive carbon steel.

The increase in the total corrosion rate attributable to galvanic coupling between corroding and passive carbon steel is relatively small at 2.4%.

The increase in the total corrosion rate attributable to galvanic coupling between corroding carbon steel and stainless steel is insignificant at 1.0%.

In 3% NaCl solution, the galvanic current between various types of stainless steel and corroding carbon steel is at least half the current rate compared to the effect between carbon steel and corroding carbon steel.

With increasing concrete resistivity, the induced galvanic coupling current is reduced at an increasing rate.

The presentation is available here.

Assessment of stainless steel reinforcement for concrete structures rehabilitation (Galvanic Coupling)

Galvanic Coupling between stainless steel and carbon steel

Journal of Constructional Steel Research (2008)

J. T. Perez-Quiroz, et al

The paper presents an investigation of the galvanic coupling behavior in the case of 304 type stainless steel connected to the existing carbon steel in the rehabilitation of concrete structures. Based on a number of standard electrochemical tests the galvanic coupling current of connecting stainless steel with corroding carbon is much less than the effect of connecting passive carbon to corroding carbon steel—the net effect is that connecting with stainless reduces the corrosion effect.

The presentation is available here.